Satin Polished

Our satin polish has a uniform grain which generally runs down the length of the product. We supply our products with a removable plastic coating or sleeving to avoid damage, scratches and finger marks. The finish produces products which are very low maintenance and easy to clean.

Typical uses

- Splashbacks

- Handrailing

- Wall cladding

- Catering shelves/table tops

- Door/kick plates

- Signs

- Street furniture

- Shop fitting equipment

Technical details

Our satin dull polished sheets have an abrasive finish with a unidirectional grain generally produced with an aluminium oxide abrasive with a grit of approximately 240. This produces a surface that’s smoother than dull buffed but is not as fine as other finishes in our range.

On a standard cold rolled product, a dull polished finish produces a surface roughness of approximately 0.6µm Ra, which conforms to the BS EN 10088-2 2J finish. Under the old BS 1449 Part 2 specification this was a No.4 finish.

Mirror Bright Polished

Our mirror bright polish has a highly-reflective and smooth finish which makes it very low maintenance and easy to clean. Our range of mirror polished products come with a removable plastic coating or sleeving to help prevent finger marks and damage like scratches. Due to its smoothness, this is the most corrosion resistant finish on the market.

Typical uses

- High strength and unbreakable mirrors

- Marine equipment

- Catering equipment

- Signs

- Street furniture

- Shop fitting equipment

- Hygienic applications

Technical details

This reflective finish is produced with mops and compounds rather than abrasive media.

The combination of an exceptionally low Ra, as well as good reflectivity and the absence of grain, makes it suitable for extreme conditions, such as those found in marine environments. It is also excellent for architectural purposes. The low Ra means there are less areas for contaminates to sit.

On a standard mill produced sheet the surface has reflectivity at approximately 61 > 65% taken at 60 degrees. It has a surface roughness of approximately 0.05µm Ra, which conforms to the BS EN 10088-2 2P finish.

The reflectivity on tubular and long products is less than on sheets and isn’t guaranteed to match exactly.

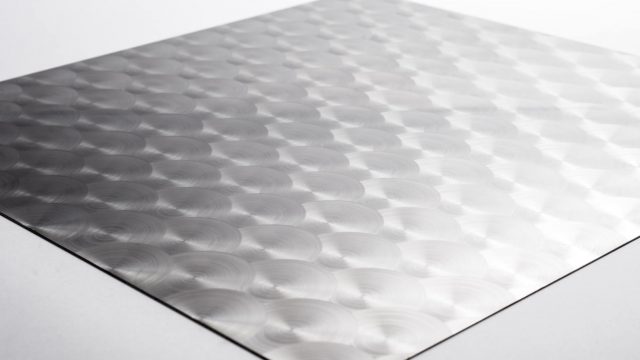

Circle polished

Our circle polished sheet has an attractive overlapping circle pattern that makes it ideal for any application that requires a decorative finish. The sheets comes with a removable plastic coating to avoid damage, scratches and finger marks. This product is very low maintenance and easy to clean.

Typical uses

- Wall cladding

- Splashbacks

- Kickplates

- Vehicle modifications

Technical details

Circle polished sheet is produced from a mechanical process that involves rotating abrasive discs contacting the sheet. Our circle polish (ProCirc ST50) is produced using 50mm discs and is the standard finish mostly seen in catering vehicles. It is ideal for architectural, catering and tank applications.

Mill finished aluminium sheets

Our aluminium sheets are sold in their natural condition.

They are produced by rolling, which gives them a natural grain and bright appearance. However they are not cosmetically finished, so may show rolling bands or stripes and can also look grainy.

If your product is going to be visible and needs to be visually appealing, you may require an anodised or painted finish.

Mill finished aluminium long products

Our aluminium long products (angles, channels, tee-section, tube etc) are offered in their natural condition.

The aluminium is heated and pushed through a die to produce the shape required. This gives it a bright finish with a natural grain.

It is not cosmetically finished it, so can show minor defects and look grainy. If your product is going to be visible and needs to be visually appealing, an anodised or painted finish may be more suitable.